Energy Efficient Lighting Upgrade at Khanh Phong Plastic Factory with Lumos Controls

Background

Khanh Phong Plastic has started building a new factory at Hai Son Industrial Park in Duc Hoa Ha, Duc Hoa Long An! The factory has three distinct areas. The first area, Zone 1, consists of the Auxiliary and Office areas. Over at Zone 2, they have two separate floors – the first-floor warehouse and the second-floor warehouse. And the third area is the production area.

Objective

The factory is designed with a natural light architecture that incorporates skylit panels arranged horizontally in the first-floor warehouse area and on the roof of the production area. This design allows ample sunlight to enter the factory during the daytime. They wanted to optimize the lighting conditions inside the factory, with the fixture lights being adjustable and can be customized based on the available natural light

Challenges

Since the factory is huge, providing adequate lighting and ensuring energy savings were challenging. It was crucial to develop a well-designed lighting plan that considers the factory’s dimensions, the various activities conducted within different areas, and the specific lighting needs of each section. One additional concern raised was the installation height of the lights, which was set at 12 meters. However, this height can pose challenges when it comes to running wires from each light fixture to a central control point. This process can be time-consuming and often necessitates extensive modifications to the existing electrical infrastructure of the building.

Solutions

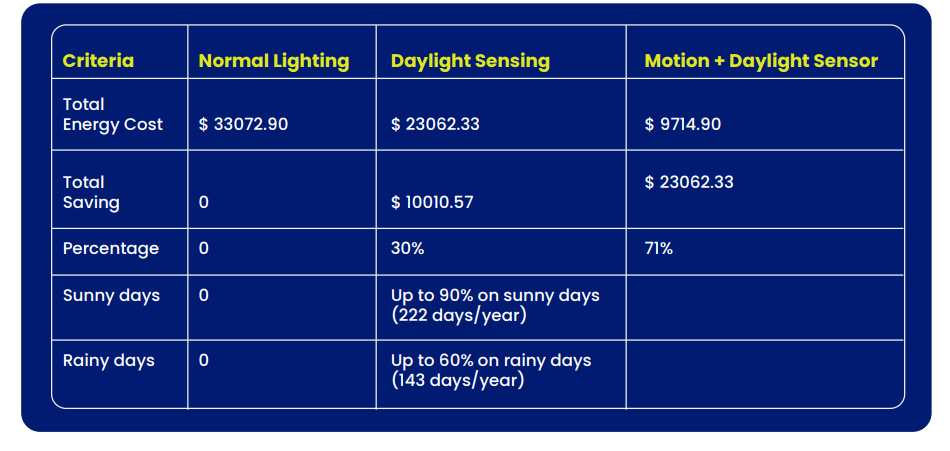

We offered 0-10v dual channel controllers, Motion and Daylight Sensor, and 4 button switches. Since the fixtures are wirelessly connected to sensors, the large open spaces could be broken into smaller control zones through programming instead of wiring. As the factory is designed with natural light architecture, the sensors successfully implemented an open-loop control system, effectively regulating the output of fixture lights indoors depending upon the availability of natural light thereby significantly reducing energy consumption. Also, the implementation of occupancy motion sensors in the factory offers a highly effective solution for reducing energy consumption by automatically detecting periods of inactivity and promptly turning off lights

Result

Supercharge Your Lighting! Feel free to connect now?